The future of energy

With the possibilities offered by our storage facilities, the energy future has already begun. It is no longer just about storing natural gas, which is where we started. The future is about storing green gases such as hydrogen.

Everyone now agrees that the sustainable transformation of the energy system can only succeed with large-volume, high performance storage options for gaseous energy sources. The expansion of renewables alone is not enough and misses the all-important question: How can green electricity be brought into the winter? We not only need clean energy, but also maximum security of supply. Energy must be available flexibly and in large quantities in line with demand - all year round - not just in summer when the sun is shining or the wind is blowing. In our latitudes in particular, it is therefore important to bring the summer sun into the windless winter, to decouple production from short-term consumption and thus create security of supply all year round. This can be achieved by converting electricity into hydrogen and storing it in our storage facilities.

Our subsurface engineering expertise, technological capabilities and innovative capacity have allowed us to develop “sustainable energy mining” approaches.

RAG is pursuing a strategy for the sustainable after-use of natural gas production sites. Each of our reservoirs is evaluated to assess its longterm suitability for energy storage, green gas or geothermal projects. A large proportion of our natural gas reservoirs have already been converted into storage facilities for natural gas and other energy forms.

RAG’s “sustainable energy mining” approach is set to spark innovation in Austrian industry, cut transport-related greenhouse gas emissions, boost economic growth in the regions and reduce dependence on energy imports.

Sector coupling refers to the networking of and collaboration between the power, gas, heating and industrial sectors to create the integrated energy system of the future.

Cross-sectoral collaboration between energy production businesses, electricity and gas infrastructure, and industry is pivotal to the development of a sustainable energy system and to significant reductions in carbon dioxide emissions.

The major expansion of renewable energy generation required to meet climate protection targets represents a formidable challenge for security of supply and for existing energy infrastructure, which needs to be able to cope with the growth in erratic renewable power generation.

The answer: renewable energy forms are converted into green gas (hydrogen and, subsequently, natural gas) through electrolysis. This means that a portion of the energy collected from the sun and the wind in summer can be stored as gas, in underground pore reservoirs, to be used in winter and/or produce synthetic methane by means of natural processes. The stored energy can be withdrawn in large quantities at any time as required, and quickly delivered using existing infrastructure.

Research & Innovation

RAG has a long track record of close involvement with new technologies that will make it possible to store and utilise large volumes of renewable energy efficiently.

RAG has decades of experience of producing, utilising and storing gas, and since 2013 the company has been working on cutting edge projects aimed at seasonal storage of hydrogen and the development of green gas technologies. RAG’s innovative capacity has enabled it to become a sustainable technology leader in the European energy storage and supply sector.

RAG has been a pioneer in the field of hydrogen production since 2015, when it brought Austria’s first megawattscale water electrolysis plant online. In addition to this, in collaboration with a variety of industrial partners, research institutions and universities, RAG is investigating the viability of a range of methane electrolysis approaches.

Gaseous energy sources

The spectrum of gaseous energy sources is broad. It ranges from conventional natural gas to green gas such as hydrogen.

Gaseous energy sources are required in every area of life: to heat homes, generate electricity safely, fuel clean transportation, and for affordable industrial production.

Energy in the form of gas can be transported out of sight underground, stored in very large quantities and made available quickly in large volumes. Gas can be produced from renewable energy sources (wind and solar energy) and thus stored.

Natural gas is a raw material with universal applications. Deposits are principally composed of methane (CH4) - a simple compound of carbon (C) and hydrogen (H), which can be bonded and separated synthetically. This compound will spearhead our progress towards a renewable energy future.

Hydrocarbons are formed from organic material such as animal and plant remains. Microorganisms and algae that live in water sink to the sea bed when they die and become embedded in mud. This leads to the formation of what is called source rock - a layer of mud which oxygen cannot reach. Over time, the source rock is covered by more and more layers of mud, leading to increases in pressure and temperature. Under such conditions, dead organic material turns into kerogen, and ultimately into hydrocarbons, which then migrate from the source rock to adjoining layers with higher porosity, such as sandstone. If this sandstone is sealed by a layer of rock, the conditions are in place for the formation of a gas field.

The process by which organic matter turns into gas began hundreds of millions of years ago below ground, and is still in progress today.

The term 'green gas' refers to all gaseous energy forms that enable carbon-free, low-carbon or carbon-neutral production and consumption: it can be produced using wind power, solar energy or biomass. Whether in the shape of hydrogen produced using methane splitting, biomethane, or naturally produced green gas - gaseous energy sources are the future. Green gas not only has vast potential, it is sustainable, affordable and storable.

Gas is particularly efficient: in combined heat and power (CHP) plants, where thermal energy from gas is used to generate heat as well as electricity, efficiency is close to 90%. And if gas is used in a condensing boiler, efficiency can reach 96%.

It can be stored in large volumes and is suitable for below-ground transport. RAG's subterranean gas storage facilities contain around 71 TWh - all of Austria's pumped storage plants combined can store around 0.14 TWh. Both storage formats are an important part of safeguarding security of supply - by guarding against both daily and seasonal swings.

Storage

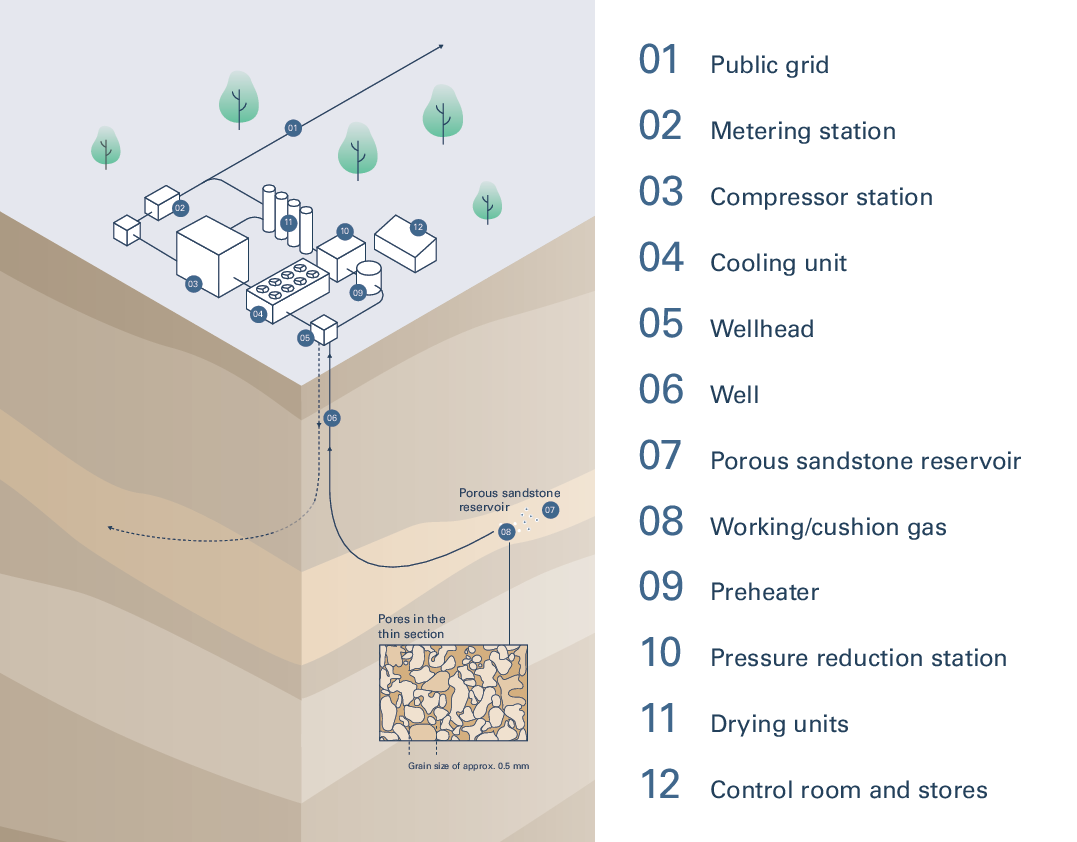

When gas arrives at a storage facility via a pipeline network, it first enters a metering station where it is filtered, and the quantity and quality are measured. Injection to and withdrawal from the reservoir take place via a number of wells. Where necessary, compressors bring the incoming gas (working gas) up to the right injection pressure.

Since compression raises the temperature, the gas must then be cooled before being conveyed to the wellhead and injected into the natural rock formations. It's vital to ensure that the original reservoir pressure is never exceeded.

Working gas is injected and withdrawn as required, which cuts operating costs and helps maintain high environmental standards.

Whenever the gas is withdrawn it must be reprocessed. It must be dried and cleaned as it will have absorbed moisture in the reservoir. Once "on-specification", it enters the grid and is transported to the consumer.

Austria's energy storage facilities shoulder the responsibility for long-term, high-volume energy storage, ensuring that seasonal imbalances can be evened out. As energy generation from renewable sources grows, the need for large-volume, seasonal storage capacity also increases, in order to balance out the seasonal swings from energy surplus (excess solar energy in summer) to deficit (increased demand due to low temperatures in winter). Storage enables accustomed levels of supply security to be maintained at all times.

With a total storage capacity of more than 6.2 billion cubic metres (bn cu m), RAG's energy storage facilities make a major contribution to security of supply in Central Europe. Barely any other EU member state has such high storage capacity in comparison with consumption. Currently still used primarily for traditional natural gas, they will in future enable the seasonal storage of green gas such as hydrogen for withdrawal at high capacity and at any time.

Several studies have investigated the hydrogen tolerance of gas infrastructure: one such example, the Underground Sun Storage project, demonstrated that existing infrastructure copes well with hydrogen content of up to 10% (20% in the USC project). The Underground Sun Storage 2030 follow-up project will test the hydrogen tolerance of our storage facilities for contents of up to 100%.

These projects raise the prospect of repositioning natural gas storage facilities, with their enormous storage capacity, as hydrogen stores in the energy system of the future. They will play the role of large-scale, seasonal storage facilities for renewable energy, just as RAG's gas storage facilities do today.

RAG operates and continues to develop a total of 11 pore storage facilities in Upper Austria and Salzburg. These include the storage facilities in Puchkirchen/Haag, Haidach, Haidach 5, Aigelsbrunn and the 7Fields interconnected gas storage as well as the hydrogen storage facilities in Pilsbach and Rubensdorf.

Mobility

Liquefied natural gas (LNG) is natural gas that has been converted to a fluid aggregate state by cooling it to a temperature of around -163°C. Liquefaction makes it possible to transport and store 600 times as much energy in the same space. The gas can be produced in Austria or transported to customers in specially designed road, barge and sea-going tankers.

Chemically speaking, liquefied biogas (LBG) is liquid methane, so it is identical to LNG and can be used for exactly the same purposes; the difference is that it comes from renewable sources, meaning that it is particularly environmentally friendly. RAG is collaborating with Hitachi Zosen Inova AG to produce renewable organic LNG, a fuel which will allow trucks to run emission-free using locally-sourced fuel.

Compressed natural gas (CNG) is used in compressed gaseous form to fuel cars: it primarily comprises natural methane, biogas and, increasingly in future, green gas.

Gas is the cheapest and safest way to cut road traffic pollution. It has been used as an especially economical, safe and clean vehicle fuel in Austria and around the world for decades. The advantages are obvious: reduced nitrogen oxide emissions, reduced fine particulate emissions, reduced noise.

- LNG

Gas is the ideal fuel for heavy goods vehicles. LNG-powered trucks are suitable for long-haul journeys: a single tankful is enough to cover more than 1,500 kilometres with a 40-tonne load, and emissions are lower than from an equivalent trip made using diesel. In economic terms, LNG is already the best available alternative to diesel, and it is therefore used by many environmentally-aware hauliers. Another advantage is the exemption for LNG vehicles from toll charges in Germany.

- CNG

In the form of CNG, methane is also an affordable and eco-friendly alternative to conventional fuels for passenger vehicles. Using CNG vehicles can significantly improve air quality, especially in urban areas. CNG vehicles are also quieter. Natural gas burns more slowly, and hence more gently, making it only about half as noisy as diesel.

RAG operates LNG and CNG filling stations, giving drivers easier access to environmentally friendly, affordable natural gas.

- LNG

RAG has been operating Austria's first LNG filling station at Ennshafen port in Upper Austria since September 2017. In 2019 it added another in Graz in partnership with F. Leitner Mineralöle GmbH. Both stations are open around the clock, every day of the year. For legal reasons, drivers are required to complete brief training before they are allowed to use the unstaffed facility.

- CNG

Since June 2016, RAG has operated two CNG filling stations in Gampern and Kremsmünster in Upper Austria. These self-service, unstaffed stations are open around the clock, every day of the year. In the coming years, further natural gas filling stations connected to RAG's production and storage operations will be opened to the public.

For business customers, we also offer construction and operation of natural gas filling stations that allow your fleet to conveniently and economically refuel at your own site. Gas is supplied from regional production plants or from our secure underground storage facilities.

- LNG

For legal reasons, drivers are only allowed to use our unstaffed LNG filling stations after completing brief training.

- CNG

In principle, the procedure for filling up vehicles with CNG is largely the same as that for conventional liquid fuels such as gasoline and diesel. It takes around the same length of time, with the only exception being that CNG is pumped into the vehicle's fuel tank via the hose as a gas. Most gas-powered cars are equipped with a bi-fuel drive system, meaning the engine can run on petrol as well as methane, and there is a separate fuel tank for petrol. Switching between fuels takes place automatically without the driver even noticing, even while the vehicle is in motion.

Safety & environmental protection

Safety is one of RAG's top priorities. We ensure safe places to work for all of our employees, as well as safe living environments for local residents and the local authorities where we operate by meeting the very highest safety standards.

Use of the latest technology, outstanding continuous training for our team, and forward-looking maintenance of our facilities are reflected in our exceptional quality, workplace safety and environmental protection standards. Health, safety and the environment are the pillars of our management system, which plays a central role at our company.

On the basis of clear processes, precisely defined guidelines and instructions, and efficient communication we go one step further, setting ourselves a target of zero accidents in all of our activities. Besides the health and safety measures designed to protect our own workforce, we also integrate contractors closely into our safety activities.

Together with safety and environmental protection, sustainable and responsible stewardship of Austria's natural resources are paramount in everything we do. We pay particularly close attention to maximising environmental sustainability, optimising energy use, cutting emissions, use of waste avoidance technology, new methods for continuous surveillance and testing of plant and pipelines, as well as IT security and integrity management.